客户背景介绍:

![]()

该集团于1984年在中国北京成立,自1997年起,该企业一直蝉联中国国内市场销量第一,占中国个人电脑市场超过三成份额。到今天已经发展成全球领先的科技企业,2014年跃居《财富》世界500强第286位,已成为全球第一大个人电脑厂商。

该企业于2012年在武汉市东湖高新区投资设立移动互联(武汉)生产基地项目,建设预计总投资达50亿人民币的生产基地项目、移动互联及数字家庭运营中心项目及其相关配套等。移动互联(武汉)生产基地座落于中国光谷东湖开发区高新四路,总规划面积20万平米,以智能手机、pad产品制造为主,整个产业基地产能规划1亿台,员工规模10000人。

客户遇到哪些问题:

![]()

○ 设备是独立的,人机不分离,造成人等待机器,降低工作效率;

○ 由于物料补充方式及工序设计不合理导致各工位间产生大量等待时机;

○ 现场5S差;

针对性解决方案:

![]()

项目开展花絮:

![]() .

.

线体亮点:

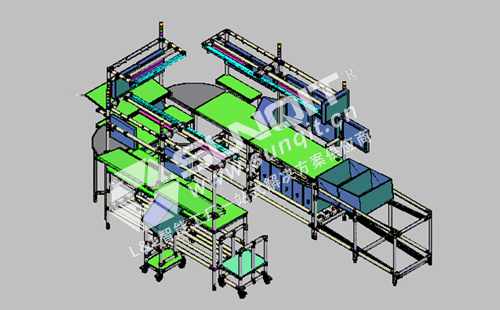

![]()

1、设备采用灵活、可拆解、镶入式设备台架车,高度、水平距离根据员工的需求可调;

2、称重工位采用设备镶入式(设备水平面与工作台操作面一致);

3、将员工反复不增值的拿取动作剔除同时提高现场5S;

4、防止不良最终流入客户端;

5、设备(独立单元)与柔性线体的无缝对接,消除人等待机器;

6、提高工作效率,单件流,质量可追溯;

效益分享:

![]()

参考Callisto系列需求(改善后):2016年产能:45万台/年(22天、10.5h制)TT≈25s,人员配置:6人(含1名“水蜘蛛”)

| 序号 |

项目名称 |

改善前 | 改善后 | 效果 | 节省成本(单位:万元) |

|

1 |

生产平衡率 |

40% |

95% |

提升产线平衡率 |

隐性节约成本 |

| 2 | 线体柔性 | 77% | 95% | 满足市场变化需求 | 隐性节约成本 |

| 3 | 5S | 差 | 好 | 激发员工作业激情 | 隐性节约成本 |

| 4 | UPPH | 22台/h | 28.8台/h | 人均效率预计提高30% | 117040元/年(参考4000元/月)计算公式:(年需求 /实际月产能)*人数*月工资-(同公式改善后数据) |

| 显性节约成本: | 117040元/年 | ||||